工业生产中经常会用到胶水,但对于一些较难粘接的材料,普通胶水就没辙了。对于从事特种胶研发23年的0111来说,今天就跟大家盘点下客户咨询最多,认为“超难粘”的几种材料,看看都有哪些粘接方案吧!

硅胶制品

特性:硅胶具有非常光滑的表面,传统胶水对其的粘附效果较差。

解决方案:可使用420AB快干胶进行粘接,该胶水具有流动性好、定位快、粘性强、耐老化等特点。产品通过欧盟ROHS标准和SGS检测,安全、环保,可放心使用。

![]()

使用方法:

1.将要粘接的硅胶材料用干棉布将其表面的灰尘、油污等擦去。

2.再以0111系列无毒环保无腐蚀性专用清洗剂擦拭,清洁粘合表面。

3.然后用滴管吸取一定胶水,控制出胶量,将胶水滴在要粘接材料的表面。

4.把涂了胶水的两个面进行对粘,保持15秒左右,待胶水表面固化。

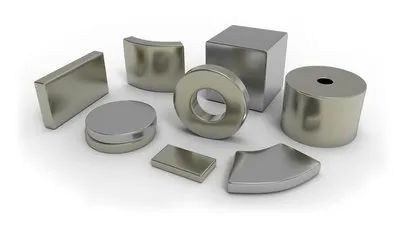

金属表面

特性:金属材料常常会与胶水发生反应或产生半导体效应,从而导致传统胶水的粘附力减弱。

解决方案:可使用530金属胶水进行粘接,该胶水具有高粘度、高强度、柔韧性好、耐老化、粘好后的产品可用于室外等特点。产品通过欧盟ROHS标准和SGS检测,安全、环保,可放心使用。

使用方法:

1.将要粘接的金属材料用干棉布将其表面的灰尘、油污等擦去;

2.再以0111系列无毒环保无腐蚀性专用清洗剂擦拭,清洁粘合表面;

3.然后用滴管吸取一定胶水,控制出胶量,将胶水滴在要粘接材料的表面;

4.把涂了胶水的两个面进行对粘,保持20s左右,待胶水表面固化。

聚氨酯(PU)

特性:聚氨酯材料通常含有添加剂,这些添加剂会干扰胶水与材料的黏附力。

解决方案:可使用P208或P218胶水进行粘接,P208或P218胶水具有耐老化性、耐热性好,不拉丝,方便操作,在UV光或阳光照射下,耐黄变性极佳,粘合力强等特性。产品 通过欧盟ROHS标准和SGS检测,安全、环保,可放心使用。

使用方法:

1.将要粘接的PU材料用干棉布将其表面的灰尘、油污等擦去;

2.再以0111系列无毒环保无腐蚀性专用清洗剂擦拭,清洁粘合表面;

3.然后用滴管吸取一定胶水,控制出胶量,将胶水滴在要粘接材料的两个面上进行对粘,一定要充分粘接到位;

4.把涂了胶水的两个面进行对粘,保持5s左右,待胶水表面固化。

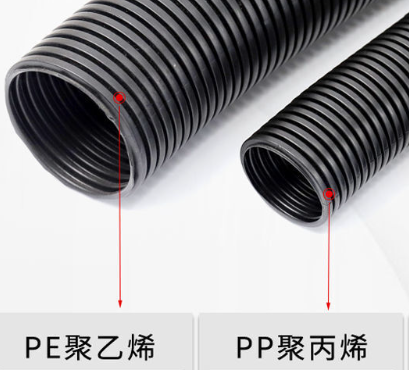

聚乙烯(PE)和聚丙烯(PP)

特性:这些塑料属于惰性材料,使得胶水很难在其表面形成牢固的粘附。

解决方案:可以使用T360慢干胶水或320AB快干胶水进行粘接,T360胶水为慢干胶,胶水固化时间较长,使用时采用刷涂;320AB胶水为快干胶,胶水固化时间较短,使用时采用滴涂。两种胶水都具有无刺激性,高透明、不拉丝,粘接后表面柔软,耐老化性等特性。产品通过欧盟ROHS标准和SGS检测,安全、环保,可放心使用。

使用方法:

1.将要粘接的PP、PE材料用干棉布将其表面的灰尘、油污等擦去;

2.再以0111系列无毒环保无腐蚀性专用清洗剂擦拭,清洁粘合表面;

3.若粘接面较小,则用滴管吸取一定量320AB胶水,控制出胶量,将胶水滴在要粘接材料的表面;若粘接面较大,则使用毛刷将T360刷涂在大型粘接面上;

4.把涂了胶水的两个面进行对粘,保持5s左右,待胶水表面固化。

您有任何粘接难题,添加咱们特种胶水客服微信,把样品寄给我们,我们免费为您提供咨询打样服务!

Do you know of the four materials considered “super difficult to stick”?

In industrial production, adhesive is often used, but regular adhesive may not work for some materials that are difficult to bond. For 0111, which has been engaged in the research and development of special adhesives for 23 years, let’s take a look at the several materials that are considered 'super difficult to stick' and the adhesive solutions that are frequently inquired about by customers.

Silicone products

Characteristics:

Silicone has a very smooth surface, and traditional adhesives have poor adhesion to it.

Solution:

420AB fast-drying adhesive can be used for bonding, which has the characteristics of good fluidity, quick positioning, strong adhesion, and aging resistance. The product has passed the EU ROHS standard and SGS testing, which is safe, environmentally friendly, and can be used with confidence.

Instructions:

1.Use a dry cotton cloth to wipe off the dust, oil stains, etc. on the surface of the silicone material to be bonded.

2.Then wipe the bonding surface with a non-toxic, environmentally friendly, and non-corrosive specialized cleaning agent from the 0111 series.

3.Use a dropper to take a certain amount of adhesive, control the amount of the glue, and drip the glue on the surface of the material to be bonded.

4.Bond the two surfaces coated with glue, hold for about 15 seconds, and wait for the glue surface to solidify.

Metal surface

Characteristics:

Metal materials often react with adhesives or produce a semiconductor effect, which leads to a weakening of the adhesive strength of traditional adhesives.

Solution:

The 530 Metal Adhesive can be used for bonding. This adhesive has high viscosity, high strength, good flexibility, aging resistance, and can be used for outdoor applications. The product meets the EU ROHS standards and has been tested by SGS for safety and environmental friendliness, so you can use it with confidence.

Instructions:

1.Wipe off the dust and oil stains on the surface of the metal materials to be bonded with a dry cotton cloth;

2.Wipe the bonding surface with a 0111 series non-toxic, environmentally friendly and non-corrosive special cleaning agent;

3.Then use a dropper to extract a certain amount of adhesive and control the amount of glue. Drops the adhesive on the surface of the material to be bonded;

4.Bond the two surfaces coated with glue together, hold for about 20 seconds, and wait for the surface of the adhesive to solidify.

Polyurethane(PU)

Characteristics:

PU materials usually contain additives, which can interfere with the adhesive strength between the adhesive and the material.

Solution:

You can use P208 or P218 adhesive for bonding. P208 or P218 adhesive has good aging resistance, heat resistance, non-stringing properties, and easy operation. It exhibits excellent resistance to yellowing and deformation under UV light or sunlight, and has strong adhesive strength. The product meets the EU ROHS standards and has been tested by SGS for safety and environmental friendliness, so you can use it with confidence.

Instructions:

1.Wipe off the dust and oil stains on the surface of the PU material to be bonded with a dry cotton cloth;

2.Wipe the bonding surface with a 0111 series non-toxic, environmentally friendly and non-corrosive special cleaning agent;

3.Then use a dropper to extract a certain amount of adhesive and control the amount of glue. Apply the adhesive to both surfaces of the material to be bonded, and make sure it is fully bonded in place;

4.Bond the two surfaces coated with glue together, hold for about 5 seconds, and wait for the surface of the adhesive to solidify.

Polyethylene (PE) and polypropylene (PP)

Characteristics:

These plastics are inert materials, making it difficult for adhesives to form strong adhesion on their surfaces.

Solution:

You can use T360 slow-drying adhesive or 320AB fast-drying adhesive for bonding. T360 adhesive is a slow-drying adhesive with a longer curing time, and it is applied by brush. 320AB adhesive is a fast-drying adhesive with a shorter curing time, and it is applied by dripping. Both adhesives are non-irritating, highly transparent, non-stringing, and have soft surfaces and good aging resistance after bonding. The products comply with the EU ROHS standard and have been tested by SGS for safety and environmental friendliness, so they can be used with confidence.

Instructions for use:

1.Use a dry cotton cloth to wipe off the dust, oil, and other contaminants on the surface of the PP and PE materials.

2.Then, wipe the bonding surface with a non-toxic, environmentally friendly, and non-corrosive specialized cleaning agent from the 0111 series to ensure a clean bonding surface.

3.For small bonding surfaces, use a dropper to take a certain amount of 320AB adhesive, control the amount of adhesive, and drop it onto the surface of the materials to be bonded. For larger bonding surfaces, use a brush to apply T360 adhesive on the surface.

4.Press the two adhesive-coated surfaces together and hold for about 5 seconds until the adhesive surface solidifies.