通常胶带结构中,基材是用来涂胶或印刷的载体。

常用基材

按照大类,胶带的基材可以分为:膜类/纸类、透明基材/不透明基材、软质或拉伸性基材/硬质无拉伸性基材、耐高温基材/耐低温基材、自毁基材/自修复基材。

而常用的胶带基材有这些——

膜类:PET、BOPP、PVC、PP、PE、TPU、珠光膜、合成纸

纸类:牛皮纸 、和纸 、棉纸、美纹纸、硫酸纸

其它基材:PE泡棉、EVA泡棉、聚氨酯泡棉、网格布、布基材料、铝箔、绒布、弹力布、无纺布、玻纤布、化纤布

特殊材料:特殊纸类材料 、特殊膜类材料、耐高温面材 、耐低温面材、可拉伸性面材、自修复性面材、自毁性面材、光学级面材

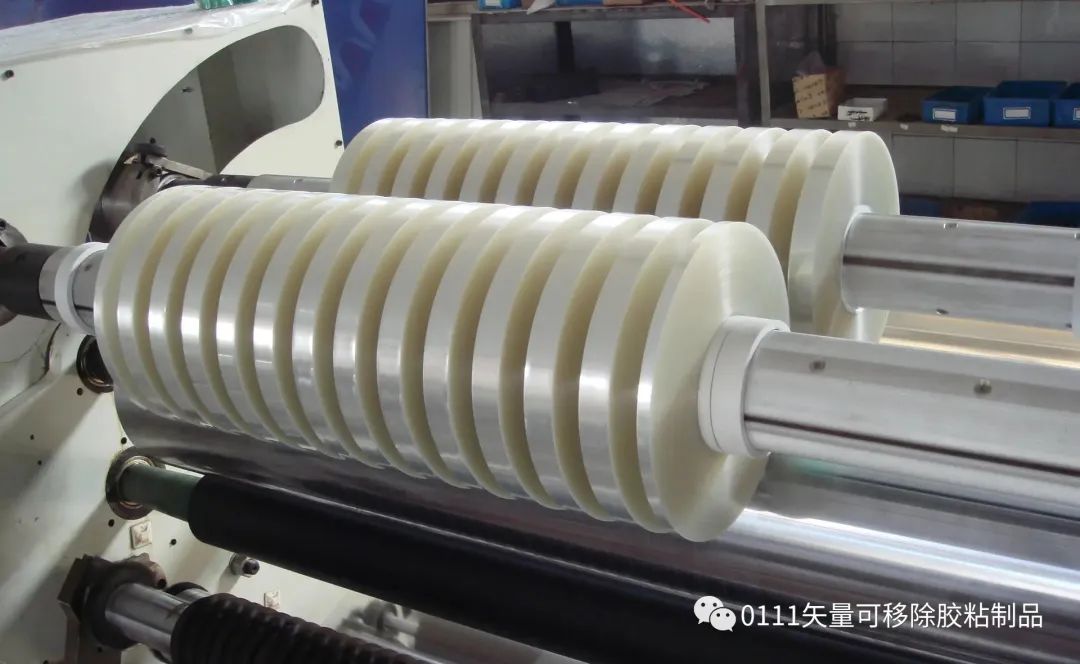

基材结构

在胶带的生产中,由于基材的各种材质、各种厚度(0.012um至5mm)的不同,对在基材的表面进行涂层或电晕处理。

涂层处理是根据材质和涂的胶水不同,会有不同的处理,来增加表面的附着力;打电晕是通过高压电产生的火花对材质表面进行破坏,在表面形成一层附着力。总的来说,这两种处理方式都是为了使印刷及涂胶效果更好。

想了解更多资讯的小伙伴,也可以扫码关注我们的抖音官方账号!

Useful Tips | What are the commonly used substrate materials for tape? And what are the processing methods in production?

In general tape structures, the substrate is the carrier used for adhesive coating or printing.

Commonly used substrates

According to categories, tape substrates can be divided into film/paper, transparent substrate/opaque substrate, flexible or stretchable substrate/rigid non-stretchable substrate, high-temperature resistant substrate/low-temperature resistant substrate, self-destructive substrate/self-healing substrate.

Some commonly used tape substrates include:

Films: PET, BOPP, PVC, PP, PE, TPU, pearl film, synthetic paper

Papers: Kraft paper, Washi paper, cotton paper, textured paper, sulfite paper

Other substrates: PE foam, EVA foam, polyurethane foam, mesh fabric, fabric materials, aluminum foil, velvet fabric, elastic fabric, non-woven fabric, fiberglass cloth, synthetic fabric

Special materials: special paper materials, special film materials, high-temperature resistant face material, low-temperature resistant face material, stretchable face material, self-healing face material, self-destructive face material, optical-grade face material

Substrate Structure

In tape production, different coating or corona treatment is applied to the surface of the substrate due to the different materials and thicknesses (ranging from 0.012um to 5mm) of the substrate.

Coating treatment varies based on the material and adhesive used to enhance surface adhesion. Corona treatment involves using high-voltage electricity to create sparks that damage the material surface and create an adhesive layer. These two methods are generally used to improve the printing and adhesive effects.