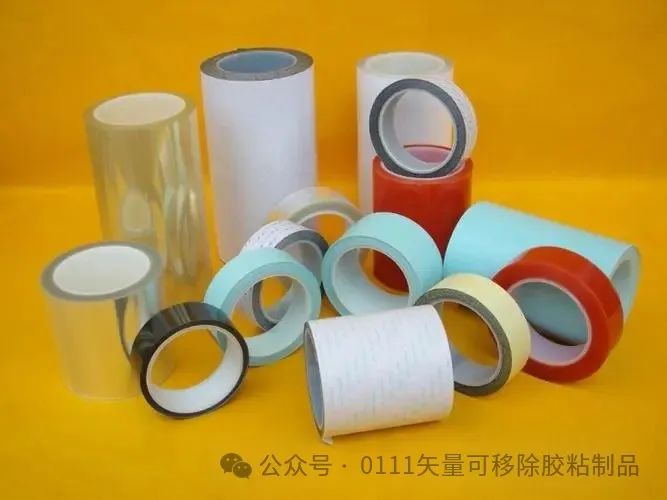

常用的可移除压敏胶系分为可移除水胶系、可移除油胶系、可移除热熔胶系。今天我们就来讲讲可移除油胶系。

可移除油胶系的学名叫丙烯酸酯压敏胶,日常我们叫做亚克力胶水。

相比水胶系、热熔胶系、UV压敏胶系、有机硅压敏胶系等其他常见胶系,亚克力胶的综合性能最佳,因此它的应用也是最广泛的。

-

亚克力胶的气味相对较低。相比水胶系及热熔胶系气味稍高,相比UV压敏胶系及有机硅压敏胶系气味算低的。

-

生产车速快,因为有机溶剂的挥发速度快所致

-

成本适中,虽没有水胶和热熔胶的成本低,但相比UV压敏胶和有机硅压敏胶系算低的

-

含有机溶剂(天那水),固含量低45%左右,胶体的内聚力差

-

耐低温性能和高低温兼容性差,普通配方在手指揉搓胶面会有拉丝及反粘现象,低温环境胶面粘性明显变弱

-

胶面对各种材质长时间的粘贴可移除性能都不会太好,个别材质(玻璃/烤漆/大理石)在特定的环境(常温环境)下有短时间(3至6个月左右)的可移除性,最终还是要根据每个厂家的技术及配方来决定可移除性能

-

生产时溶剂的挥发气味大,对环境、车间以及对生产人员都不是那么友好,有一定的安全隐患

由于可移除亚克力胶的可移除时间短和限制较多,为了改变可移除性能,通常会采用加稀释剂或者增加固化剂的方法,具体原理如下。

方法2:通过加大固化剂的添加量,来增加胶体的内聚力,从而也会大大减低了胶水的初粘力。

想了解更多资讯的小伙伴,也可以扫码关注我们的抖音官方账号!

Useful tips | Advantages and Disadvantages of Removable Adhesives, You’ll Understand After Reading This!

The commonly used removable pressure-sensitive adhesives are divided into three categories: removable water-based adhesives, removable solvent-based adhesives, and removable hot-melt adhesives. Today, let's talk about removable solvent-based adhesives.

What is a removable solvent-based adhesive?

The scientific name for removable solvent-based adhesive is acrylic pressure-sensitive adhesive, commonly known as acrylic glue.

Pros and cons of removable solvent-based adhesive

Compared to other common adhesive types such as water-based adhesives, hot-melt adhesives, UV pressure-sensitive adhesives, and silicone pressure-sensitive adhesives, acrylic adhesive has the best overall performance, making it the most widely used.

Pros:

- Acrylic adhesive has a relatively low odor. Compared to water-based and hot-melt adhesives, the odor is slightly higher, but lower compared to UV pressure-sensitive adhesives and silicone pressure-sensitive adhesives.

- Fast production speed due to the quick volatilization of organic solvents.

- Moderate cost. Although it is not as low-cost as water-based and hot-melt adhesives, it is relatively lower compared to UV pressure-sensitive adhesives and silicone pressure-sensitive adhesives.

Cons:

- Contains organic solvents, with a low solid content of about 45%, resulting in weak cohesive strength of the adhesive.

- Poor low-temperature resistance and compatibility with high/low temperatures. Normal formulations exhibit stringiness and anti-adhesive phenomena when rubbed between fingers, and the adhesive strength significantly weakens in low-temperature environments.

- The adhesive performance for long-term bonding on various materials is not ideal, although some materials (glass/paint/marble) may have short-term (around 3 to 6 months) removability in specific environments (room temperature). The final removability is determined by the technology and formulation of each manufacturer.

- During production, the volatilization of solvents produces a strong odor, which is not environmentally friendly, friendly to workshops, or safe for production personnel.

Improving removability

Due to the short removal time and limitations of removable acrylic adhesive, adjustments are commonly made by adding diluents or increasing curing agents. The specific principles are as follows:

Method 1: When the equipment precision is not enough or the adhesive thickness remains unchanged, the solid content of the original adhesive can be adjusted by adding diluents to reduce the thickness of the dried adhesive, thus reducing the initial tackiness of the adhesive and improving removability.

Method 2: By increasing the amount of curing agent, the cohesive strength of the adhesive is increased, thereby greatly reducing the initial tackiness of the adhesive.

However, it should be noted that due to the resinous nature of solvent-based adhesives, although the above adjustments can achieve good removability, the cohesive strength and initial tackiness will be greatly reduced or even disappear.