Glue is often used in industrial production, but for some more difficult to stick materials, ordinary glue is helpless. For 0111, who has been engaged in the research and development of special adhesives for 23 years, today I will take stock with you of the most customer inquiries and several materials that are considered "super difficult to stick", and see what bonding schemes are available!

Silicone products

Characteristics: Silica gel has a very smooth surface, and the adhesion effect of traditional glue is poor.

Solution: 420AB quick drying adhesive can be used for bonding, which has the characteristics of good fluidity, fast positioning, strong viscosity and aging resistance. Products through the EU ROHS standards and SGS testing, safe, environmental protection, can be used with confidence.

![]()

How to use:

1. Wipe the dust and oil on the surface of the silicone material to be bonded with a dry cotton cloth.

2. Then wipe with 0111 series non-toxic environmental protection non-corrosive special cleaning agent to clean the adhesive surface.

3. Then use a dropper to absorb a certain amount of glue, control the amount of glue, and drop the glue on the surface of the material to be bonded.

4. Glue the two surfaces coated with glue and hold them for about 15 seconds until the glue surface is cured.

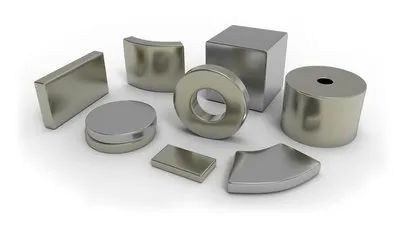

Metal surface

Characteristics: Metal materials often react with glue or produce semiconductor effects, which leads to the weakening of the adhesive force of traditional glue.

Solution: 530 metal glue can be used for bonding, which has high viscosity, high strength, good flexibility, aging resistance, and can be used outdoors after bonding. Products through the EU ROHS standards and SGS testing, safe, environmental protection, can be used with confidence.

How to use:

1. Wipe the dust and oil on the surface of the metal material to be bonded with a dry cotton cloth;

2. Then wipe with 0111 series non-toxic environmental protection non-corrosive special cleaning agent to clean the adhesive surface;

3. Then use a dropper to absorb a certain amount of glue, control the amount of glue, and drop the glue on the surface of the material to be bonded;

4. Glue the two surfaces coated with glue and keep them for about 20 seconds until the glue surface is cured.

Polyurethane (PU)

Characteristics: Polyurethane materials usually contain additives that interfere with the adhesion of the glue to the material.

Solution: P208 or P218 glue can be used for bonding, P208 or P218 glue has aging resistance, good heat resistance, no wire drawing, easy to operate, in UV light or sunlight, excellent yellow resistance, strong adhesion and other characteristics. Products through the EU ROHS standards and SGS testing, safe, environmental protection, can be used with confidence.

How to use:

1. Wipe the dust and oil on the surface of the PU material to be bonded with a dry cotton cloth;

2. Then wipe with 0111 series non-toxic environmental protection non-corrosive special cleaning agent to clean the adhesive surface;

3. Then use a dropper to absorb a certain amount of glue, control the amount of glue, and glue the glue drops on the two faces of the material to be glued, and be sure to fully stick to the position;

4. Glue the two surfaces coated with glue and hold them for about 5 seconds until the surface of the glue is cured.

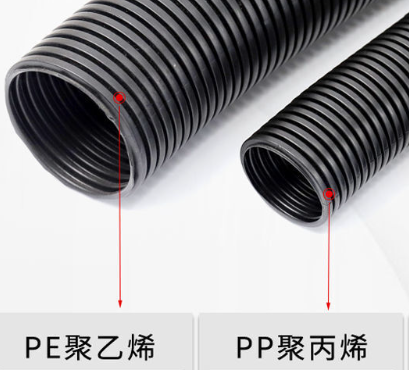

Polyethylene (PE) and Polypropylene (PP)

Characteristics: These plastics are inert materials, making it difficult for glue to form a firm adhesion on their surface.

Solution: T360 slow drying glue or 320AB fast drying glue can be used for bonding. T360 glue is a slow drying glue with a long curing time. 320AB glue is a fast drying glue, the glue curing time is short, the use of drip coating. Both kinds of glue have the characteristics of non-irritant, high transparency, no wire drawing, soft surface after bonding, aging resistance and so on. Products through the EU ROHS standards and SGS testing, safe, environmental protection, can be used with confidence.

How to use:

1. Wipe the dust and oil on the surface of the PP and PE materials to be bonded with dry cotton cloth;

2. Then wipe with 0111 series non-toxic environmental protection non-corrosive special cleaning agent to clean the adhesive surface;

3. If the bonding surface is small, use a dropper to absorb a certain amount of 320AB glue, control the amount of glue, and drop the glue on the surface of the material to be bonded; If the bonding surface is large, use a brush to apply the T360 brush on the large bonding surface;

4. Glue the two surfaces coated with glue and hold them for about 5 seconds until the surface of the glue is cured.

You have any bonding problems, add our special glue customer service wechat, send the sample to us, we provide you with free consulting proofing services!