常用的可移除压敏胶系分为可移除水胶系、可移除油胶系、可移除热熔胶系。今天我们就来讲讲可移除热熔胶系。

什么是可移除热熔胶系?

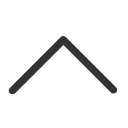

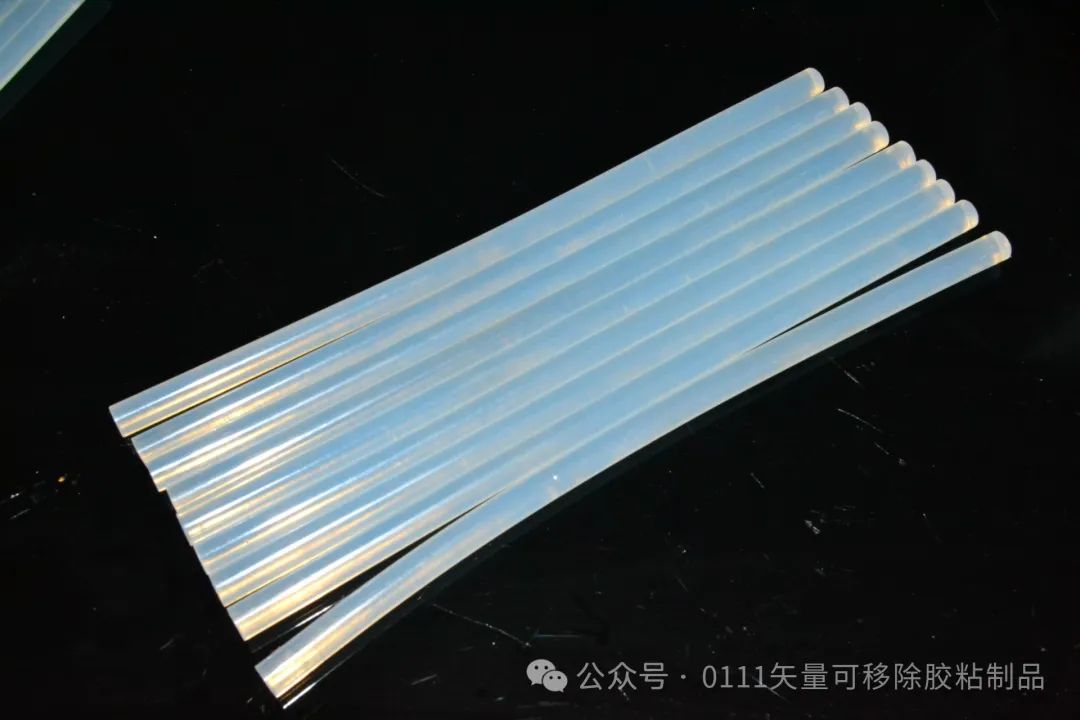

可移除热熔胶系是无溶剂、固态型的压敏胶,以胶块、胶砖为主,通过熔胶炉加温成液态,并采用专用设备完成涂布工艺。

可移除热熔胶的优缺点

与其他胶系相比,热熔胶不需要添加天那水,因此使用起来更加环保。但也由于它的特性,在性能上也有短板。

优点:

- 相比水胶系的气味会稍大一点,但是热熔胶系特有的气味,也就是增粘树脂松香的本体气味,也就是说气味的大小松香的品质来决定相比亚克力胶系气味稍低,相比UV压敏胶系及有机硅压敏胶系气味就更低了

- 生产车速快,每分钟300米以上的车速已非常普遍,而且产线非常短,胶体固化无需加热烘道,因为热熔胶水是冷却即可成型,成本比亚克力胶系更低;在要求不高的领域应用,可以通过不同技术配方做到比水胶系的成本还低

- 无溶剂100%固含,成本更低

缺点:

- 胶体的内聚力差且发黄

- 耐高低温性能和高低温兼容性差,手指揉搓胶面马上有拉丝及反粘现象,低温环境胶面粘性急剧变弱,60度以上温度环境,胶体容易拉丝及容易溢胶

- 胶面对各种材质短时间内的粘贴可移除性能都不好,个别材质(玻璃/烤漆/大理石)在特定的环境(常温环境)下有短时间(半个月左右)的可移除性

如何改善可移除性

由于可移除热熔胶的可移除时间短、限制较多,为了改变可移除性能,通常会采用调整增粘树脂添加量或者调整配方的方法,具体原理如下。

方法1:通过调整增粘树脂添加量以及助剂匹配度 ,从而降低了胶的初粘力,来提升一定的可移除性能。

方法2:选择或通过配方加强主体橡胶的抗拉性,来增加胶体的内聚力,从而粘贴时不易撕裂胶体。

需要注意的是,由于热熔胶的树脂胶系特性原因,虽然通过以上的调整可以改善可移除性能,但始终很难实现较好的可移除性。

想了解更多资讯的小伙伴,也可以扫码关注我们的抖音官方账号!

Useful Tips | Pros and Cons of Removable Hot Melt Adhesive, You'll Understand After Reading This Article!

Common removable pressure-sensitive adhesive systems include removable water-based, removable oil-based, and removable hot melt adhesive systems. Today, let's talk about the removable hot melt adhesive system.

What is removable hot melt adhesive?

Removable hot melt adhesive is a solvent-free, solid-state pressure-sensitive adhesive. It is mainly in the form of blocks or bricks and is heated to a liquid state using a hot melt pot, and then applied through specialized equipment.

Pros and cons of removable hot melt adhesive

Compared to other adhesive systems, hot melt adhesives are more environmentally friendly as they do not require the addition of solvents. However, they also have some limitations in terms of performance.

Pros:

- The odor of hot melt adhesive may be slightly stronger compared to water-based adhesives, but the unique odor of hot melt adhesive, which comes from the tackifying resin rosin, depends on the quality of the rosin.It has a lower odor compared to acrylic adhesive systems and even lower odor compared to UV pressure-sensitive adhesive systems and silicone pressure-sensitive adhesive systems.

- Fast production speed with line speeds of over 300 meters per minute being common, and short production lines. The solidification of the adhesive does not require heating and drying since hot melt adhesive solidifies upon cooling, resulting in lower costs compared to acrylic adhesive systems. In less demanding applications, it can achieve even lower costs than water-based adhesives through different technological formulations.

- Solvent-free and 100% solid content, resulting in lower costs.

Cons:

- The cohesive strength of the adhesive is weak, and it may become yellowish over time.

- Poor performance in terms of high and low-temperature resistance and compatibility. When rubbed between fingers, the adhesive can experience a stringing effect and sticky residue. Its adhesive properties significantly decrease in low-temperature environments. In environments above 60 degrees Celsius, it is prone to stringing and overspreading.

- The adhesive's performance concerning short-term removability from various materials is not good. Certain materials (such as glass, painted surfaces, and marble) may exhibit short-term (around two weeks) removability in specific environments (at room temperature).

How to improve removability?

Due to the short removal time and limitations of removable hot melt adhesive, adjustments to the tackifying resin content or formulation are often made to enhance removability. The specific principles are as follows:

Method 1: By adjusting the amount of tackifying resin and matching additives, the initial tackiness of the adhesive can be reduced, thereby improving its removability to some extent.

Method 2: Select or strengthen the tensile resistance of the main rubber in the formulation to increase the cohesive strength of the adhesive, making it less likely to tear during application.

It should be noted that due to the resinous nature of hot melt adhesives, although the above adjustments can improve removability, achieving excellent removability remains challenging.